Gas Spring is a sensitive tool that before installation in die, paying attention to first and primary manual instructions is crucial.

Watch video of Alfamak Gas Spring Maintenance Instruction.

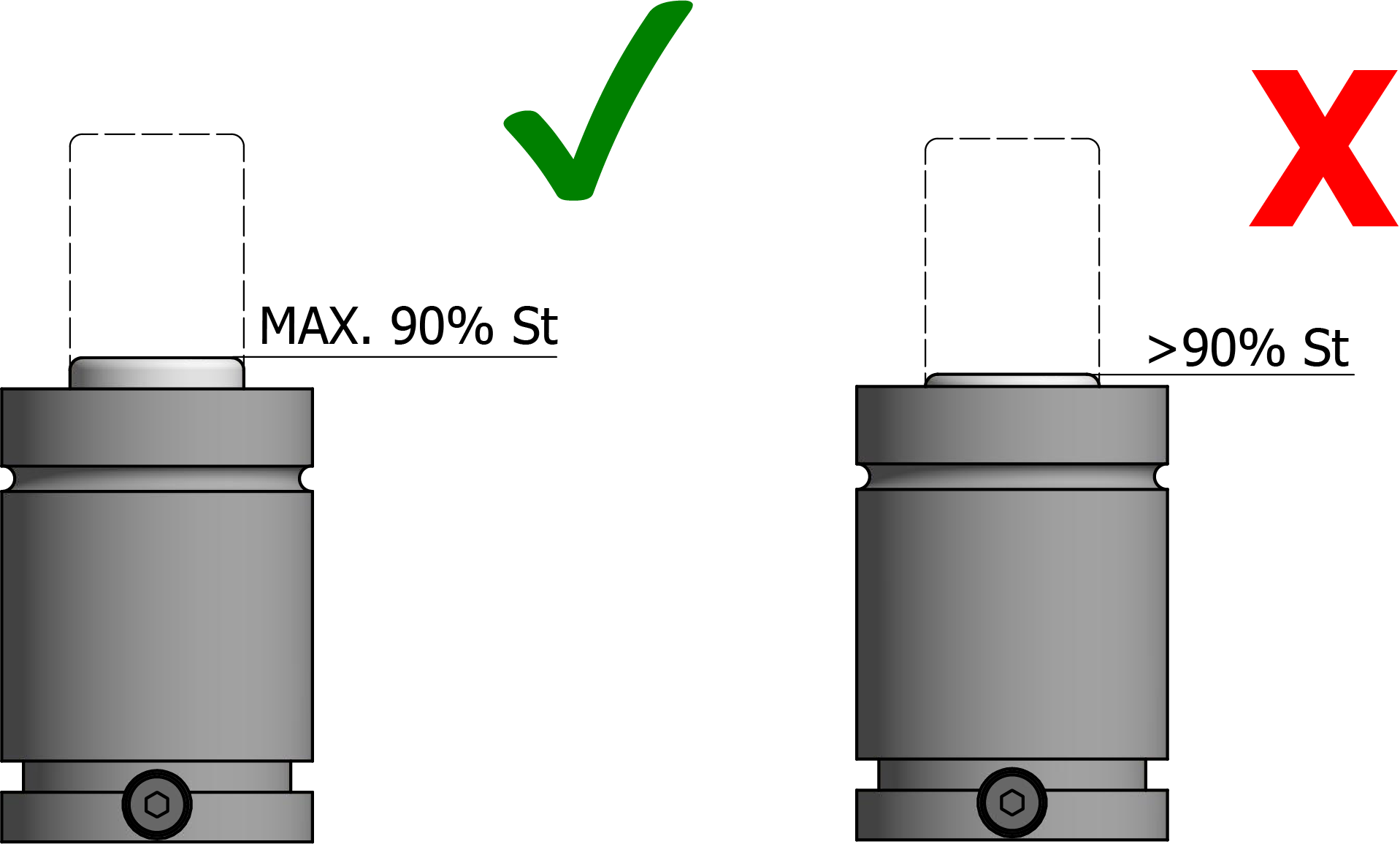

All gas springs are designed with a safety distance from 1mm to 3mm. Therefore, the nominal value (St) can be used completely. However, it is recommended not to exceed 90% of the stroke value during use to avoid the risk of overstocking caused by material changes and errors.

Do not direct the gas flow to operator when discharging the nitrogen gas.

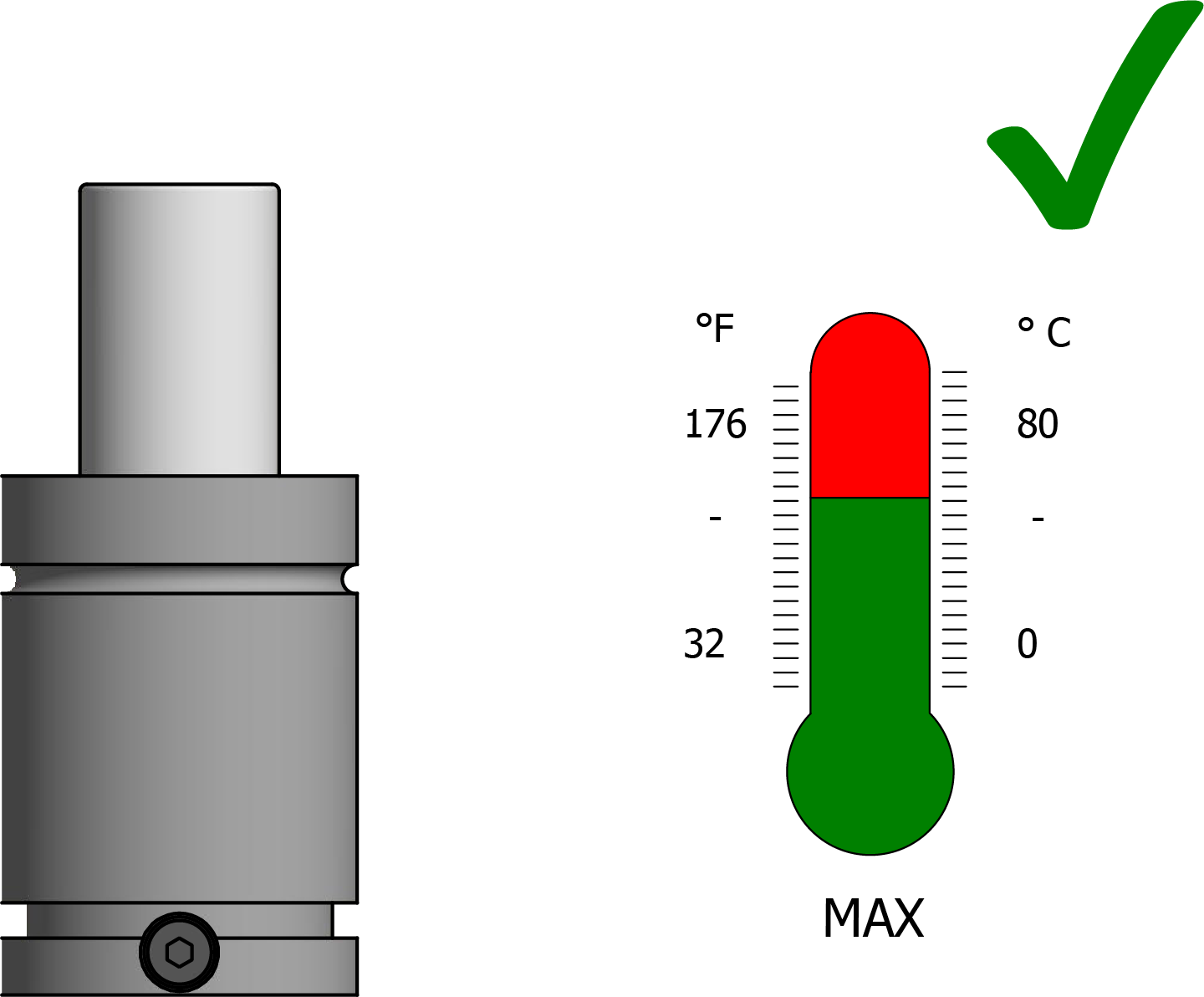

Values in the catalog are given for a temperature of 20 ° C. Changing the temperature value will cause the gas pressure to change.

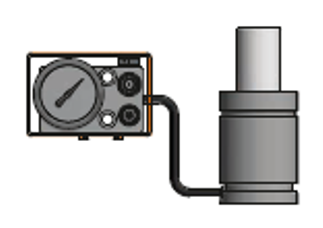

The gas spring system is supplied without gas inside all connected gas springs. (Except for K19, K25, EF170, EF320) If you want to convert gas springs into gas springs that can be connected to the system, you must order the necessary hoses and fittings and follow the special instructions prepared for the series from www.alfamak.com.

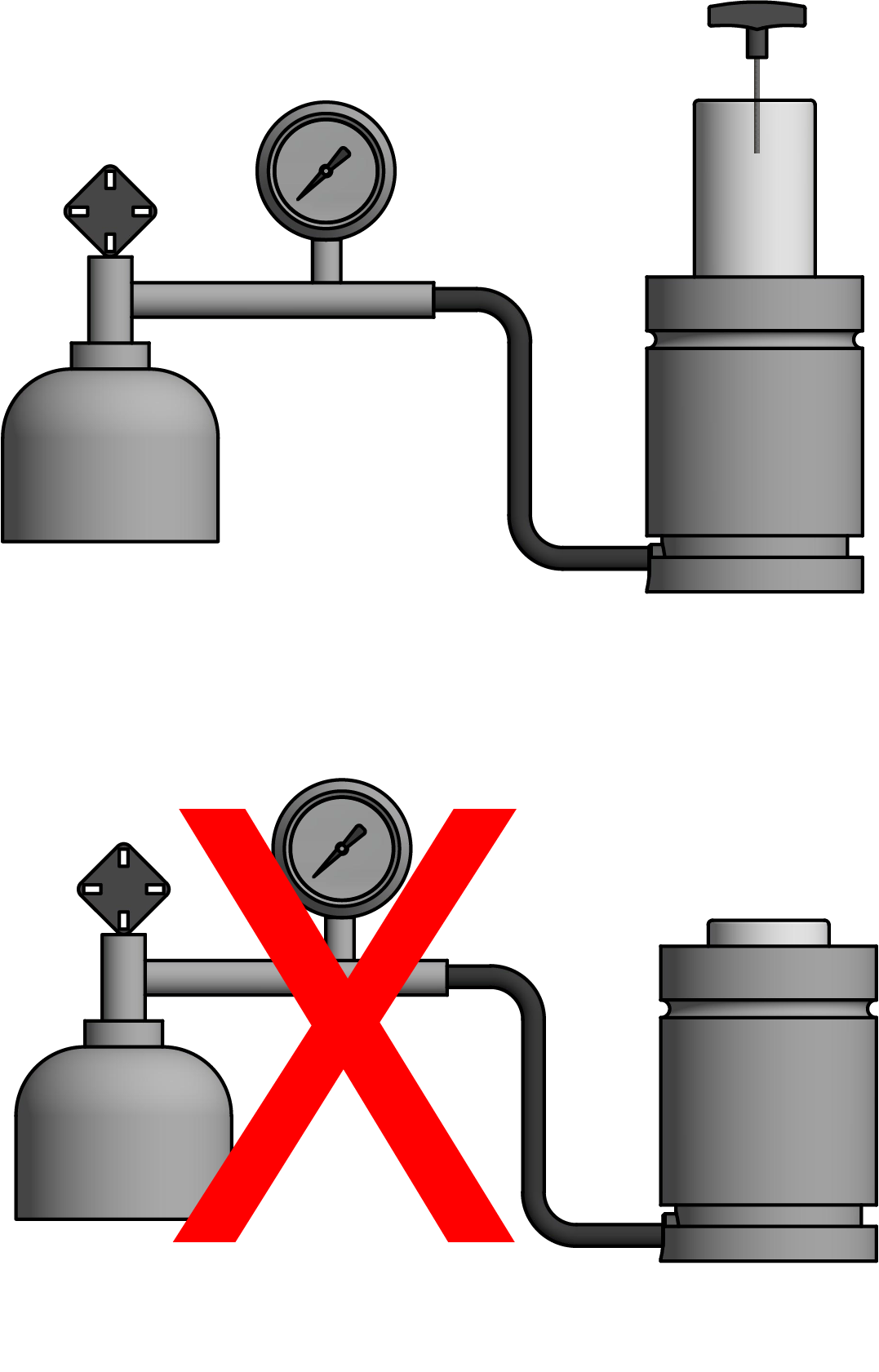

Make sure the entire shaft is removed before starting to fill the gas spring.

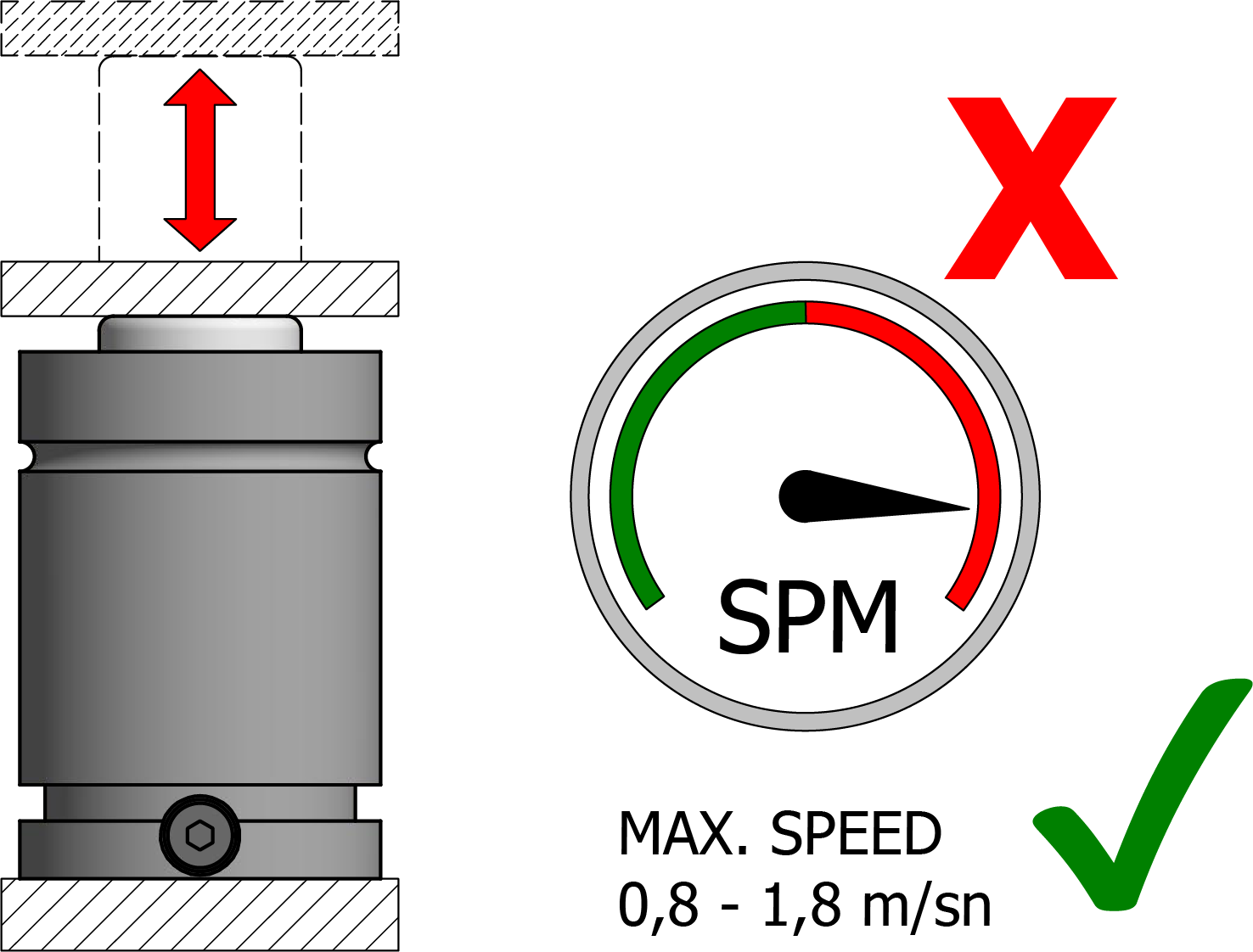

Do not confuse the speed specified for the use of gas springs with the number of strikes per minute.

If the gas spring has any structural damage, discharge all the gas (N2) inside

Charge with NITROGEN GAS (N2) only.

Operating tempreture

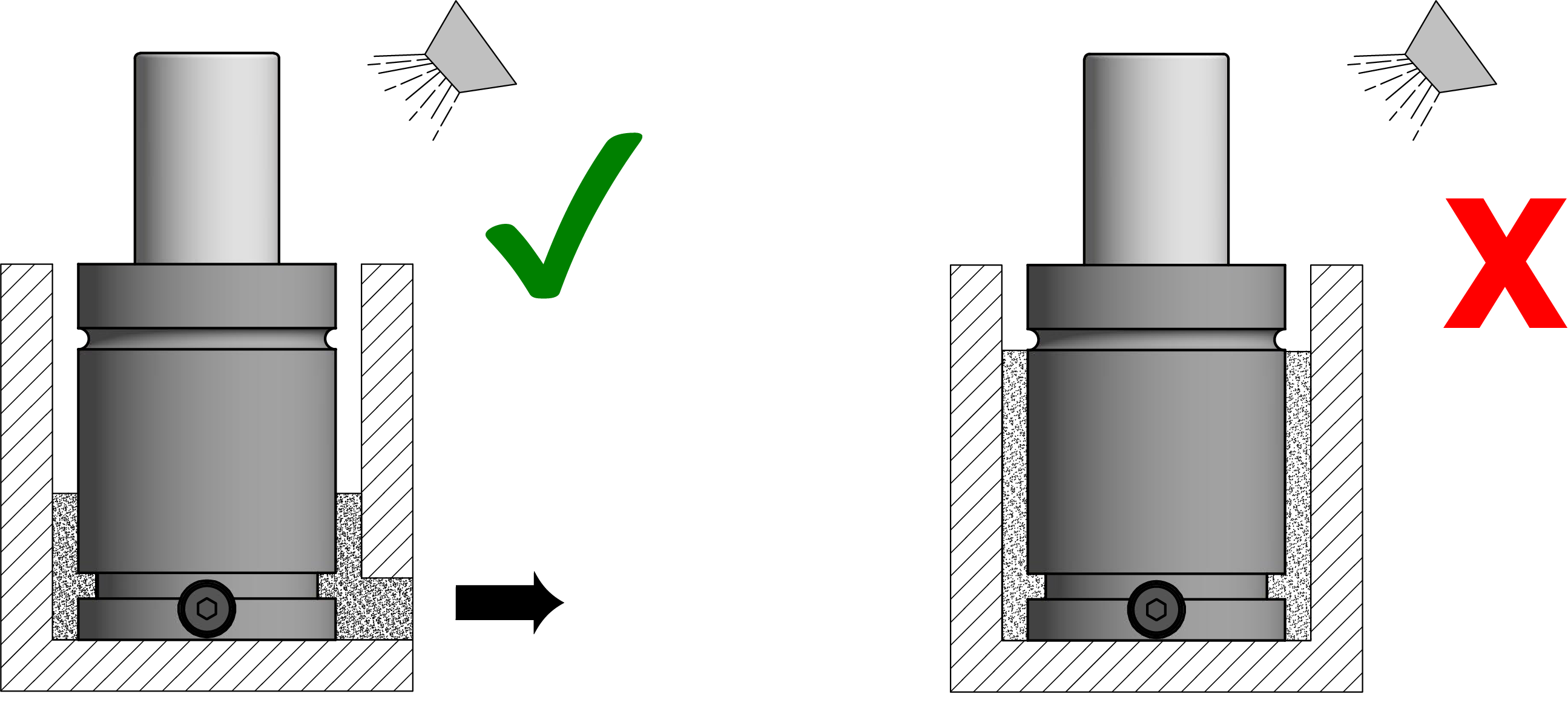

Avoid contact of gas springs with aggressive liquids (soda or chlorite). If these materials must be used for cleaning, it is recommended to carefully remove all residue from the gas springs.

Protect the body and piston rod from any structural damage.

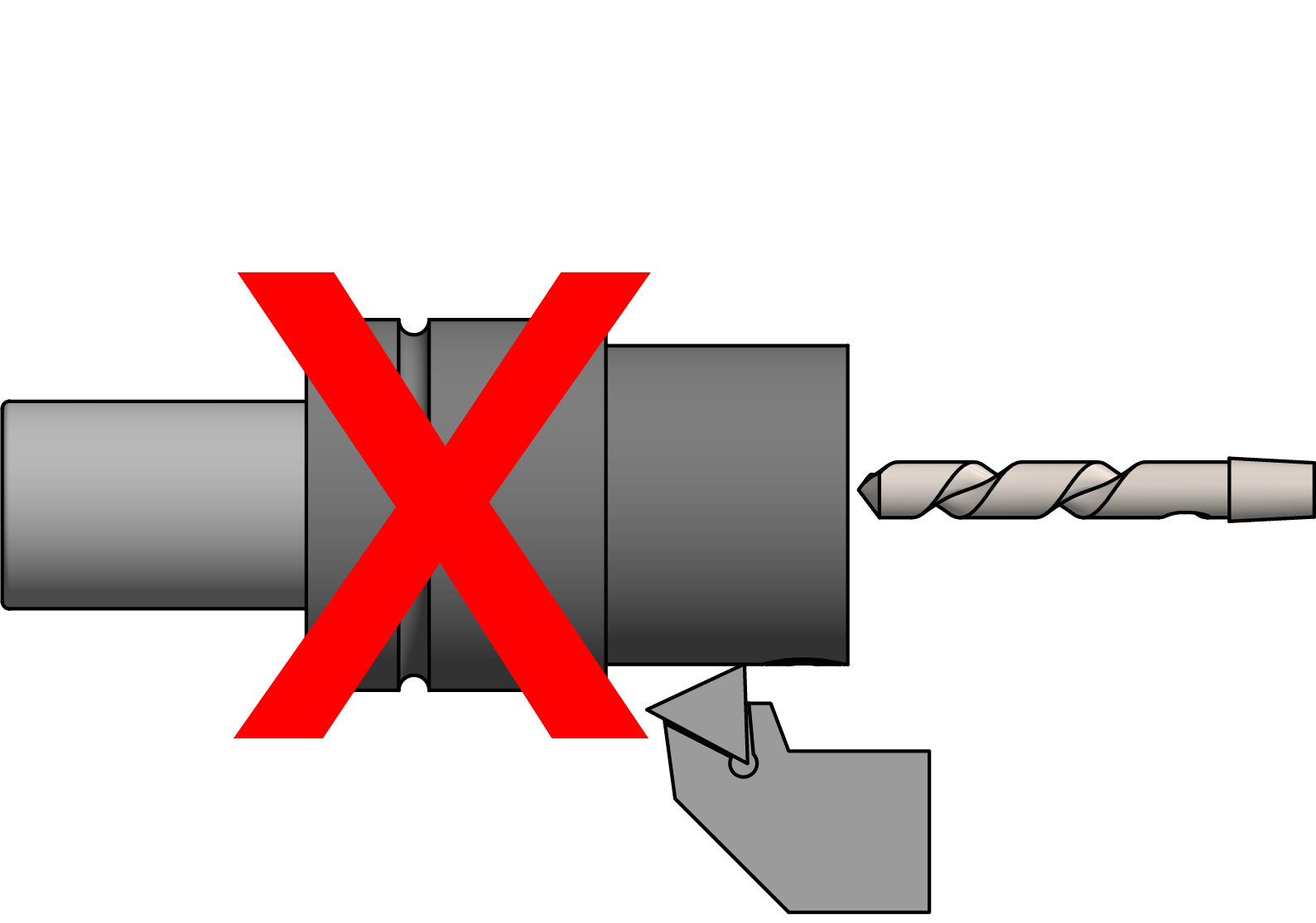

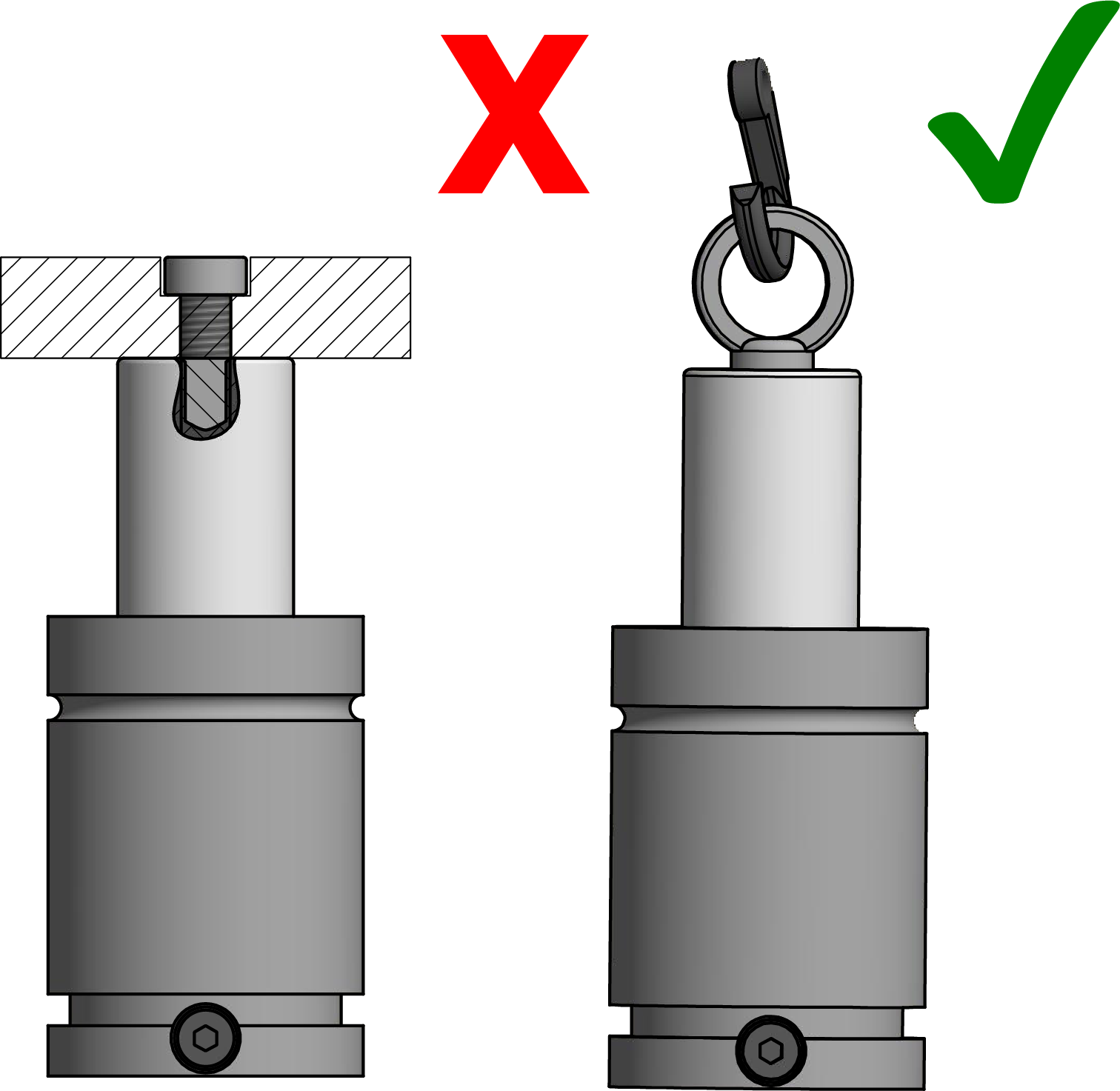

Use the threaded hole on the top of the piston rod only for gas springs maintenance.

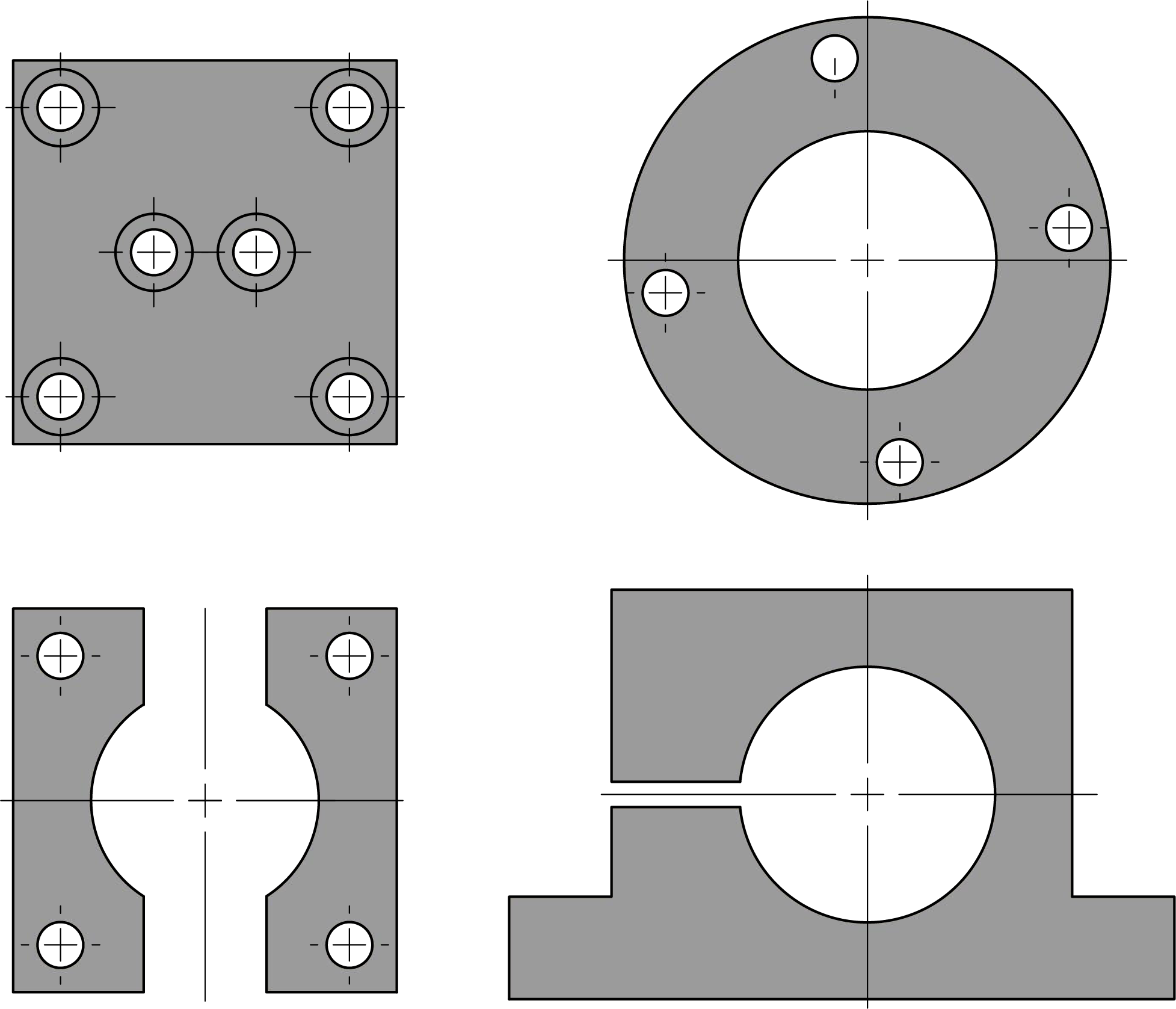

We always recommended to install the gas springs with the completely suitable fixing elements