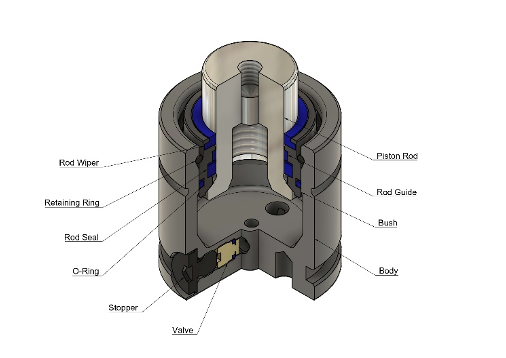

Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die.

Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring. Retaining ring and O-ring/static seal are used on the outer surface of the bush. The retaining ring is the auxiliary material that holds all the parts in the gas spring and has a high strength value. Oring/static seal is also used as a sealing element. The valve and the stopper have an important role in gas filling and evacuation. Especially the O-ring on the valve is important to ensure sealing after gas filling. All auxiliary materials used are of the highest quality and are preferred from high-strength materials. The temperature of the sealing elements should be between 20° – 80°